A Spotlight on Randa’s Internship at Sutton Tools

February 6th, 2024An exciting opportunity is waiting for young engineers at Sutton Tools. It’s about embracing a culture of knowledge sharing, cultivating a nurturing…

An exciting opportunity is waiting for young engineers at Sutton Tools. It’s about embracing a culture of knowledge sharing, cultivating a nurturing…

In a world of global trade and mass production, the value of supporting local businesses and embracing products made in one’s own…

The manufacturing and engineering industries play a significant role in Australia and worldwide, requiring extensive employment skills in various job functions….

Australian manufacturing is in the process of a making a large pivot. With the state the world is currently in; recovering from…

Sutton Tools has a long history of working in the defence sector. With our roots dating back to 1917, the company supported…

Our new SMART Manufacturing Centre is ready and we welcome you! The Sutton Tools Thomastown Victoria facility – home to our global…

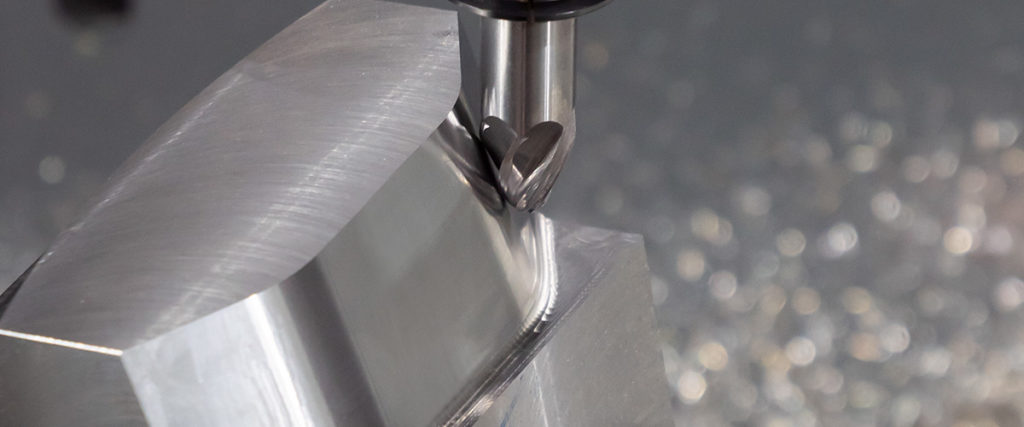

A fortuitous meeting at an industry event led to a custom solution that solves a tricky and expensive precision component manufacturing challenge….

Over many years, we’ve made it simple for our customers to manage the reconditioning of their tools in a fast and convenient…

Sutton Tools now offers a one stop shop for consumable, durable and indexable tools along with tool holding, and work holding solutions…

Jeff Boyd introduces an endmill range which is central to an exciting new initiative with Swinburne. We recently participated in the Haas…

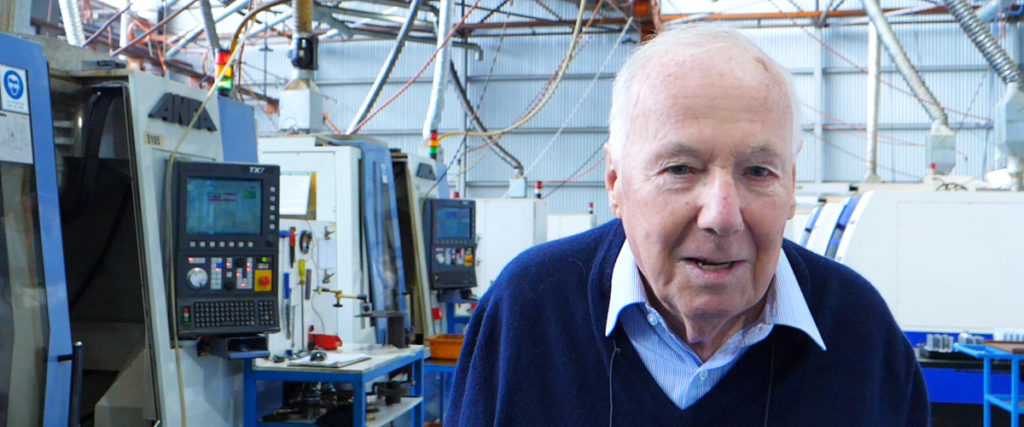

“Our goal for generations has always been to make the most durable and reliable cutting drill range available,” Jim Sutton We recently…

Sutton Tools has been a family business for over 100 years and in that time they have not only survived but thrived when faced with challenges in the domestic and…

Sutton Tools has been working to digitally transform many aspects of our operations over recent years. Rob Sutton explains how the current…

Rob Sutton explains how investment strategies can enable you to contend with low-cost competitors to achieve sustainable growth, even in tough times….

Investment in advanced CNC machinery, strategic supplier partnerships and lean manufacturing processes are enabling Brisbane-based manufacturer Eastgate Engineering to evolve and prosper….

INOX drills for tradies and weekend warriors working with stainless steel sheeting are designed to last 70% longer. Engineering Manager Tim Schurmann…

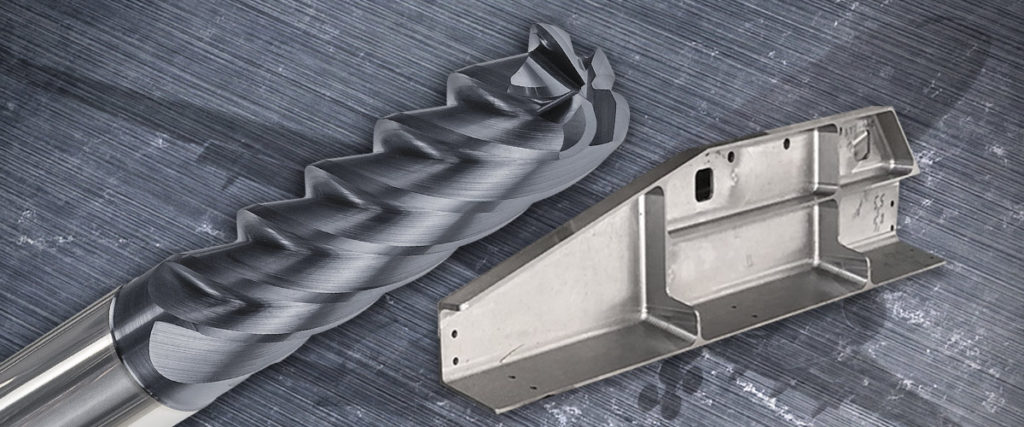

Australian-designed and manufactured taps for the automotive components industry are making their presence known in global markets, according to Jeff Boyd, Key…

Sutton Tools has had a great year for hardware industry awards in 2019! Ben Williams puts it down to the quality of…

Rob Sutton explains his belief that there are two distinct kinds of people in the world and confesses his life-long love affair…

Jeff Boyd discusses the multiple factors involved in optimising the machining processes of difficult-to-machine materials. Titanium and high-temperature alloys are some of…

Julia Kuhn is visiting Australia from Germany for a month as an intern at Sutton Tools. We spoke to her about the…

R&D Engineer Angelo Papageorgiou gives ‘too much information’ about peck drilling cycles when deep drilling in his own unique style – but…

Andrew Stevens is a former Managing Director of IBM Australia and New Zealand. Last week he was interviewed on the occasion of…

Dr Steve Dowey, Technology Manager at Sutton Tools, discusses the benefits of PVD coating of industrial cutting tools, and how pre and…

We are very proud to announce that Jimmy Toton, who has a long association with Sutton Tools, received the 2019 Young Defence…

Rob Sutton, Commercial Director of Sutton Tools, describes his experience touring the high-tech aerospace facility of ASCO in Brussels, and the future…

Peter Sutherland explains the reasoning behind estimating the cost-per-part of cutting tools – including some of the hidden costs that can add…

Even highly automated retail supply chains encounter speedbumps. James Clark outlines some of the ways we’ve streamlined the supply, receipt and warehousing…

Micro endmills are making all the difference in the medical manufacturing industry, but not just for subtractive manufacturing. One of the greatest…

We’ve long been believers in standing out from the crowd. For global manufacturers, the challenge is exactly this: providing a service that…

The survival of manufacturers depends on their ability to adapt to new technological advancements in the industry, as well as innovate new…

Where manufacturers face challenges due to cutting tool wear and damage, tool replacement might not be a cost-effective solution. Rather, a simple…

There’s a lot of talk about Industry 4.0 and Smart Factories. Dr Steve Dowey, Technology Manager at Sutton Tools, explains our approach…

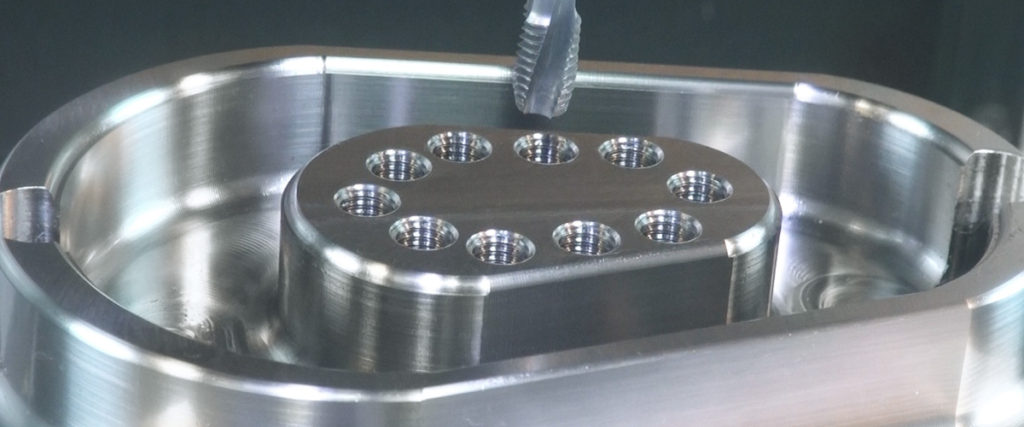

Sutton Tools’ Key Market Manager Jeff Boyd provides an example of the different results from using trochoidal versus traditional milling strategies. These…

A multinational automotive component manufacturer was experiencing inconsistent tool life at one of its Chinese plants. Sutton Tool’s Export Manager Jeff Boyd…